LED strip lighting has become increasingly popular for its energy efficiency and long lifespan. However, choosing the right LED power supply can be overwhelming for those unfamiliar with the technical specifications and features of LED strips.

I am Tom Woo, and I have been in the LED lighting industry since 2005.

In this ultimate guide, I will break down everything you need to know about LED power supplies and how to choose the best one for your needs. I will provide you with the knowledge to make the correct decision. So, whether you’re looking to upgrade your home lighting or illuminate a commercial space, this guide is for you.

What are LED power supplies?

LED power supplies, also known as LED drivers, convert electrical energy into the specific voltage and current required for LED light fixtures to function. They are designed to convert input power, such as AC or DC high or low voltage, into the output voltage and current necessary for the LED lights to operate properly and protect against various types of overvoltage, under-voltage, open circuit, and over-current issues.

LED lighting requires a specific amount of voltage and current; if this doesn’t meet their needs, they won’t work correctly or will even burn out.

An LED driver is a device that ensures a steady flow of electrical current to LED lights. In the past, these types of power sources were referred to as LED drivers, while AC-DC power supplies that provided a regulated constant voltage to LEDs were known as LED power supplies. However, today the terms “LED driver” and “LED power supply” are often used interchangeably and refer to the same device.

Why do you need an LED power supply?

An LED power supply also called an LED transformer, is necessary to power our LED strip lights safely. It is because the LED strips require a specific voltage of 12VDC or 24VDC, which is not the same as the standard mains voltage of 110VAC or 230VAC. The LED power supply converts the commercial power to the appropriate voltage for the LED strip, ensuring its proper working and protecting it from damage.

What is a good quality LED power supply?

High dependability

Stable performance over an extended period is critical to any lighting equipment. Specifically, LED street lights are designed with high-elevation driving power, making maintenance complicated and costly. But, with high dependability LED power supply, you can significantly minimize maintenance expenses.

High efficiency

LEDs are energy-efficient lighting options that require high-performance power supplies. The more efficient the LED power supply, the less power it consumes. High efficiency is not just a general energy-saving requirement for LED lighting systems. Still, also it is the foundation and guarantee for long life and increased dependability of the LED power supply. High-efficiency power supplies are characterized by their high performance, low loss, low-temperature rise, and high reliability.

For example, if a 110W LED power supply is used, the loss is 5.2W at 95% efficiency and 17.6W at 85% efficiency. The latter is 3.4 times that of the previous. Experiments have shown that under the same conditions, the former is 50 to 59 degrees Fahrenheit lower than the latter. As the power supply temperature reduces, the operating environment of the IC and power semiconductors improves, and the MTBF (mean time between failures) increases significantly.

Lowering the operating temperature of the LEDs delays light decay and extends the LED’s lifetime. For the LED power supply located in the luminaire, the temperature rise of the power supply directly leads to the temperature rise of the LED lighting fixture. An increase in the temperature of the LED chip will result in a change in the efficiency of the LED and a decrease in the electro-optical conversion performance. LEDs may fail sometimes. Some experiments have proved that for every 41 degrees Fahrenheit temperature increase of the LEDs, the flux will be 3% reduced.

The relationship between LED life and temperature is crucial, as heat is the primary killer of LEDs. LEDs running at high temperatures have a shorter lifespan. High-efficiency LED power supplies save energy and extend the life of the LED lighting system by keeping the operating temperature low.

High power factor

Power Factor (PF) measures how effectively electricity is used in a system. It is the ratio of active power, which is the power that does real work, to apparent power, which is the power that goes to the circuits. Power Factor is only applicable to AC power, not DC power. A Power Factor Corrector (PFC) is a device used to improve the power factor in a system.

Reactive power is the power taken in by inductors and capacitors in the circuits. A standard power system needs both active and reactive power to work correctly. A high power factor means more power is being used effectively and less wasted.

A high power factor in an LED power supply can significantly decrease the load on the power supply line, decrease losses, and ensure the stable operation of the lighting equipment. A low power factor indicates low power efficiency. The lower the power factor, the greater the percentage of power consumed by the distribution network. Without correction, it would require more reactive power, and the power stations would need to supply more than the active power. It can lead to the need for larger generators, transformers, and transmission lines to compensate for losses.

PFC-enabled LED power supplies can improve energy usage, minimize losses, and decrease harmonics in the grid. By increasing the power factor, PFC reduces wasted power and enhances the system’s overall efficiency.

Driving technique

Currently, there are two main methods for driving a LED power supply. The first method uses a continuous voltage source to supply several constant current sources, with each constant current source providing power to a specific section of LEDs individually. This approach offers flexibility, as a failure in one section of LEDs will not affect the operation of the other sections.

The second method uses a direct driving technique for the constant current supply, with the LEDs running in series or parallel. This method is more cost-effective but sacrifices flexibility. It also requires a solution to prevent a failure in one section of LEDs from impacting the operation of the other sections.

Both methods are currently available, and the choice between them depends on the specific application. The multiple constant current output method is more efficient and aligned with actual requirements. It is likely the mainstream direction in the future.

Surge protection

LED power supplies need to provide surge protection because LEDs are relatively susceptible to surges, particularly in their ability to withstand reverse voltage. Outdoor LED lighting products, such as street lights, are especially vulnerable to surges caused by the start of the grid load and lightning strikes. These surges can damage the LEDs, resulting in the need for frequent replacement of both the power supply and lights.

Proper surge protection is crucial for ensuring the longevity and reliability of an LED driver. Without it, the LEDs may be damaged, and the lighting system may not function as intended, resulting in costly repairs and replacements. To ensure the LED lighting system’s best performance and longest lifespan, it is important to have high-quality surge protection in place.

Protection function

LED power supply should also have a range of protection features to ensure that the LED lighting equipment operates safely and stably under various emergencies. These features may include short circuit protection, overheat protection, over current or voltage protection, etc. These protection features prevent damage to the LED lights and power supply in unusual conditions, thus ensuring that the LED lighting system runs efficiently and stably.

What are the benefits of a high-quality LED power supply?

A high-quality LED power supply lasts more than ten years: When it comes to LED lighting, you want to ensure that both the lights and the power supply will last a long time. A power supply that lasts only a year while the lights last ten years is not ideal. While using a power supply with a long lifespan of, ideally, ten years or more, you won’t have to go back and replace them in each project again, which saves you time and money.

High-reliable and long-lasting: You don’t need to replace the power supply frequently. Saving you the hassle and cost of frequent replacements. High reliable power supply will keep you from going back to each project to swap over the costly power supply.

How to Choose the Right Power Supply? Which LED power supply to choose?

AC(Alternating Current) power supply or DC(Direct Current) power supply?

1. What is AC power supply?

Alternating current, also known as high-voltage electricity, is electricity generated by power plants and distributed to homes and industries through outlets. It is characterized by its periodic change of direction, meaning it flows in one direction for a certain period and then in the opposite direction for the same period. This creates a wave-like pattern on a graph, allowing it to be transmitted over long distances.

The voltage of alternating current can vary depending on the country. In the US, it is generally 110V, while in Europe, it is 230V. However, alternating current is not ideal for precision electronic equipment, as large changes in current can damage its internal parts.

An AC power supply can power some specific LED strips. For example, we have a type of LED strip called: high voltage LED strip, which can be connected to AC230V directly without using extra power supplies.

2. What is DC power supply?

A DC power supply, which uses low voltage, is mainly used for powering devices such as storage batteries. The voltage provided by a DC power supply is stable and reliable, making it ideal for use in mobile phones, computers, and other electronic equipment that require a constant voltage.

Direct current, also known as DC, flows in a single direction, from the positive to the negative pole, making it a linear power supply. It is suitable for short-distance transportation. DC power supply converts other forms of energy into electrical energy.

LED strip lights normally operate on low voltage, such as 12VDC or 24VDC, and should be powered by a DC power supply. This is because the DC power supply provides a stable voltage, which is essential for the proper functioning of the LED strip lights.

3. What is the difference between the AC and DC power supply?

The main difference between AC and DC power is the level of voltage. AC uses high voltage, while DC uses low voltage. It is important when choosing a power supply for your LED light strip.

An AC power supply is recommended for high-voltage LED strips, while low-voltage LED strip lights, like 12V or 24V LED strip lights, should be powered by a DC power supply. It’s important to select the appropriate power supply to ensure the proper functioning of the LED lights.

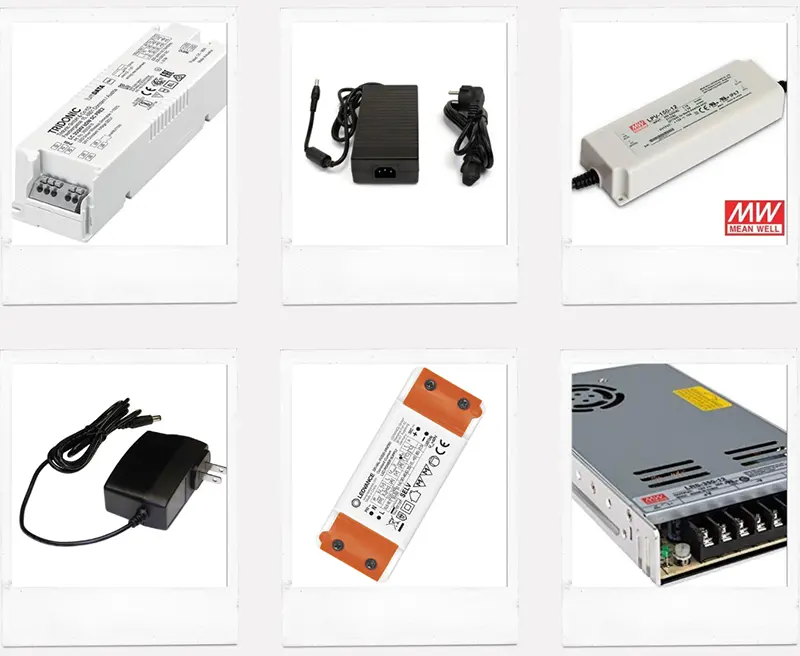

There are four types of LED power supply.

1. Laptop Style

A laptop-style LED power supply is a type of power supply designed to be small and portable, similar to the power supply of a laptop computer. These power supplies are typically used to power small LED lighting systems, such as LED strip lights. They are often used in applications where limited space and portability are essential. They are often equipped with various features such as short circuit protection, overheat protection, over-current and over-voltage protection, and more to ensure the stable and secure operation of the LED lights. They are also lightweight and compact in design, making them easy to transport and install. Overall, a laptop-style LED power supply is a compact, portable and efficient option for powering small LED lighting systems.

2. Enclosed Type

An enclosed type LED power supply is a type of power supply that is enclosed within a protective case or housing. This protective housing helps to protect the power supply from external factors such as dust, moisture, and other environmental conditions that could cause damage or malfunction. The enclosure also helps to improve the thermal management of the power supply by providing a means of dissipating heat, which can extend the life of the power supply.

Enclosed-type LED power supplies are typically used in industrial and commercial applications where the power supply needs to be protected from harsh environments. They are also designed to be durable and rugged, making them suitable for use in demanding applications.

Overall, an enclosed type LED power supply is ideal for powering LED lights in applications where the power supply needs to be protected from harsh environmental conditions and where durability is important.

Some of these power supply is specifically designed for indoor use, but they can also power waterproof LED strips as long as the power supplies are located in a dry area. It is also designed to operate efficiently with minimal heat emission, making it suitable for tight spaces.

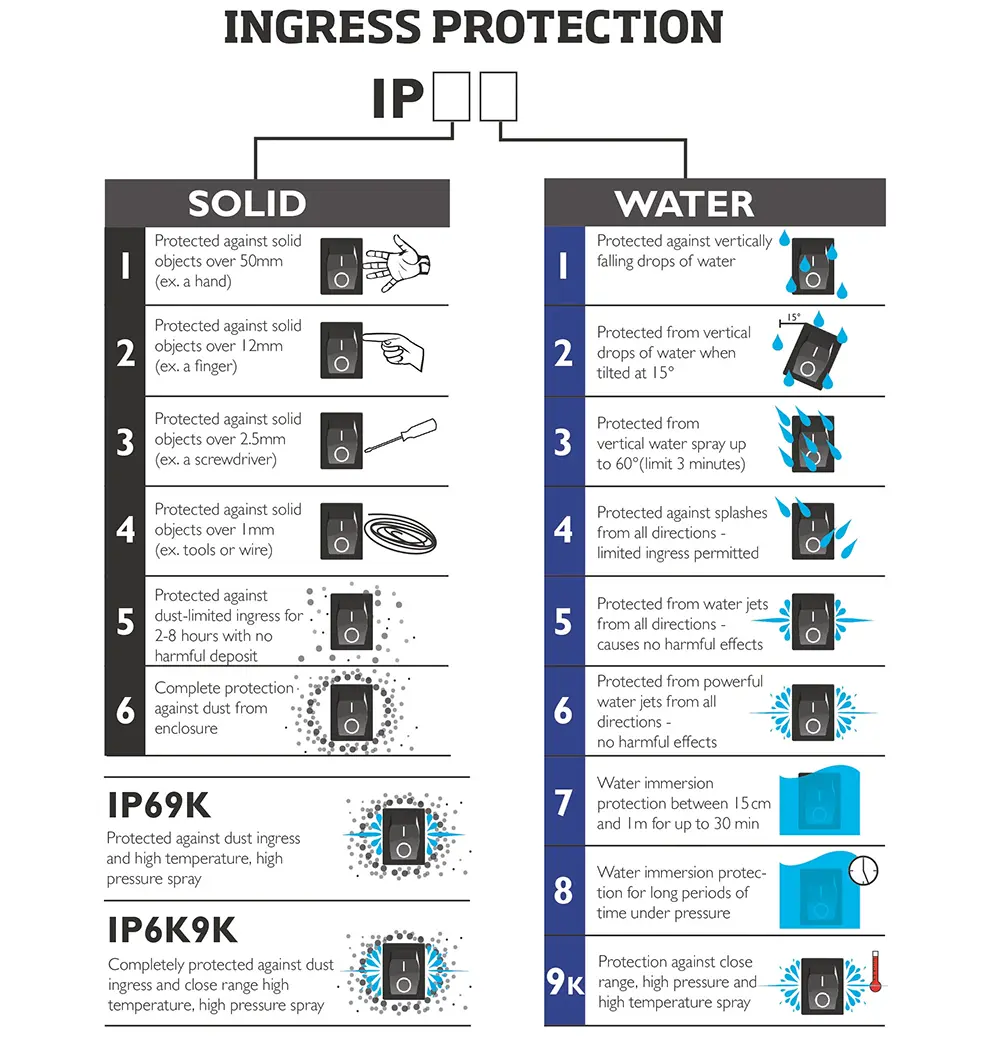

3. IP Rated

Normally these LED power supplies are IP67.

IP67 LED power supplies are power supplies that are rated IP67 for ingress protection. The “IP” stands for “Ingress Protection” and the two digits that follow indicate the level of protection against solids and liquids. In this case, the first digit (6) indicates that the power supply is completely dust-tight. The second digit (7) indicates that it is protected against the effects of immersion in water up to 1 meter for 30 minutes.

IP67-rated LED power supplies are designed to withstand harsh environmental conditions and are ideal for outdoor and industrial applications where protection against dust and water is required.

4. Open Terminal

An open terminal LED power supply is a type of power supply that does not have an enclosed housing or protective case around it. Instead, it has exposed terminals where the electrical connections are made. These power supplies are typically used when space is limited and a compact, low-profile power supply is required. They are also commonly used in DIY projects and when a user wants to create a custom power supply solution.

Open terminal LED power supplies are generally smaller and more compact than enclosed ones. They also have a lower profile and can be installed in tight spaces. However, they also have their drawback. They are not protected from environmental factors such as dust, moisture, and other environmental conditions that could cause damage or malfunction. Because of that, they should be installed in a location free from dust, moisture, and other environmental factors.

Why do some power supplies have fans, some are open terminals, and some are enclosed terminals?

Power supplies can have fans, open terminals, or enclosed terminals to cater to different usage scenarios and to ensure proper cooling, easy installation, and protection against environmental factors.

Fans are added to power supplies to help dissipate heat. Power supplies generate heat as a by-product of their operation, and if this heat is not dissipated, it can cause the power supply to malfunction or fail. Fans help to cool the power supply by blowing air over the internal components, keeping them at a safe temperature.

Open terminal power supplies are designed to be compact and low-profile. They are typically used when limited space and a compact, low-profile power supply is required, such as in DIY projects and other custom power supply solutions.

Enclosed terminal power supplies have a protective housing or case around them that protects the internal components from dust, moisture, and other environmental factors. This power supply is commonly used in outdoor and industrial applications where the power supply needs to be protected from harsh environmental conditions. They are also designed to be durable and rugged, making them suitable for use in demanding applications.

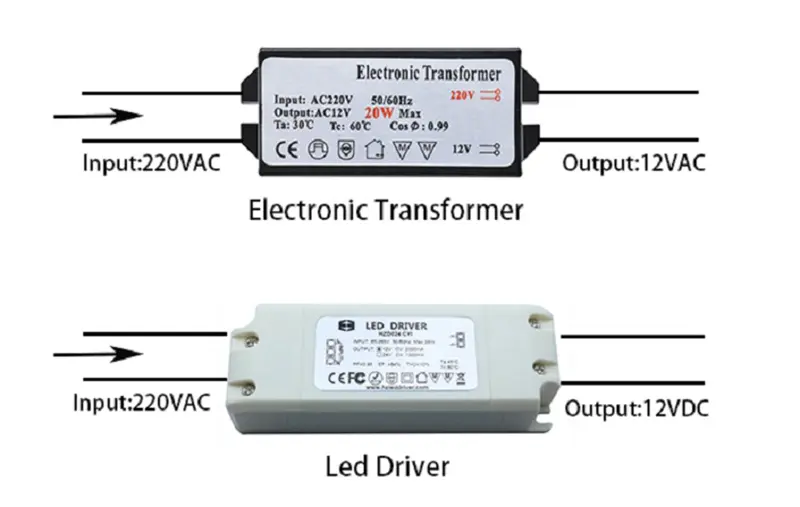

LED power supply or halogen transformer?

When converting to LED lighting, a common question is whether you can reuse an existing halogen transformer. While it may seem possible at first, it is not recommended even if the operating voltage of the LED and halogen lamps is the same. It is because many halogen transformers have specific issues that can negatively impact the performance of LED lamps. These issues include:

- High minimum load: This can cause LED lamps to remain dark or flicker.

- No constant output voltage: Voltage peaks can damage the LED lamps.

- AC output voltage: LED lamps require a DC voltage.

To ensure the proper and safe operation of your LED lighting system, it is recommended to use a dedicated LED power supply. This will provide the appropriate voltage and current for your LED lights and eliminate the risk of damage or malfunction.

Can LED power supplies be used with other types of electronic devices?

LED power supplies are designed specifically to provide power to LED lights and may not be suitable for use with other types of electronic devices. However, it depends on the LED power supply and electronic device type. It’s always good to check the power supply specifications and the device to ensure they are compatible.

Constant voltage or constant current?

What is a constant voltage LED power supply?

A constant voltage LED power supply is a type of power supply that provides a constant output voltage to connected LED lights. Constant voltage LED power supplies are typically used in applications where the number of LED lights connected to the power supply may vary, such as in outdoor or architectural lighting. The voltage output is set and is maintained constant regardless of the number of lights connected or their characteristics.

Most Unitop LED strip lights shall be used with a constant voltage power supply.

What is a constant current LED power supply?

A constant current LED power supply is an electronic device that regulates the amount of current flowing through an LED (light-emitting diode) circuit. It maintains a consistent current level, regardless of variations in voltage or temperature, to ensure that the LEDs receive the proper amount of power for optimal performance and longevity. Constant current LED power supplies are commonly used in lighting and display applications where consistent brightness and color are important.

What is the difference between constant current and constant voltage LED power supplies?

The main difference between these two types of power supplies is that a constant current power supply ensures that the LED receives a consistent amount of power. In contrast, a constant voltage power supply maintains a consistent voltage level regardless of variations in current.

You can not say which one is good or bad. It just depends on your LED lighting products and use conditions.

Input and output voltage of LED power supply

Input voltage

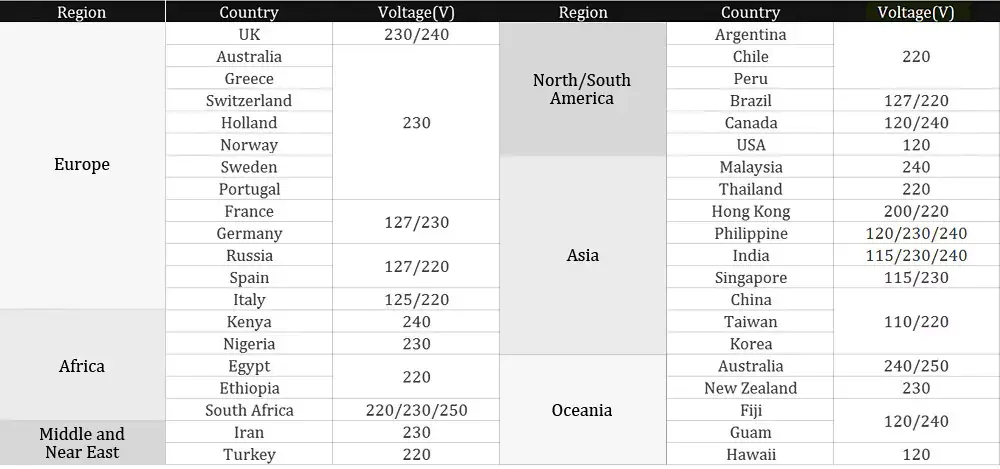

When it comes to LED power supplies, it’s important to pay attention to the range of input voltage it can handle. Check the specifications of the power supply you’re considering and ensure that it can handle the specific voltage your setup requires. For example, if you’re setting up a commercial location that runs on 277V power, you’ll want to look for a power supply that can handle that specific voltage. However, if you’re setting up a residential home with 120V or 230V power, a power supply with a wider input voltage range of 100-240V would be more suitable. Choosing the right power supply is important to ensure the optimal performance and longevity of your LED lights.

The input voltage of an LED power supply is determined by the location in which it is being used. Every country and region has a different mains voltage. For example, in China, it is 220Vac(50Hz), and in the United States, it is 120Vac(60Hz). You can refer to the “plug voltage by country” guide to know more about the voltage in a specific country.

Output voltage

When powering your LED strip lights, one crucial consideration is the output voltage of your power supply. It’s important to match the voltage of your power supply to the voltage of your LED strip lights. For example, if you have 12V LED strip lights, you’ll want to choose a 12V LED power supply. Similarly, if you have 24V LED strip lights, you’ll need a 24V LED power supply. This ensures that your lights receive the right power and function properly.

Size the LED power supply properly

Calculate LED Power Supply

Determining the power requirements for your LED lights is a simple process. The power consumption of most LED light sources, including LED spotlights, downlights, LED strip lights, etc., are listed in watts (W) and can be found on the packaging or directly on the lamp. For instance, if you use a LED lighting device with a power consumption of 20W, you’ll need a LED power supply that can supply at least 20% plus a reserve.

It’s also common to operate multiple lamps on one LED supply, which can be an efficient and cost-effective solution. In this case, you’ll need to add up the power consumption of all the LEDs used.

Calculate the power via voltage & current consumption

To calculate the power consumption of a device based on its voltage and current, you can use the formula:

Power (watts) = Voltage (volts) x Current (amps)

For example, if you have a LED lighting product that operates at 12V and has a current draw of 0.5A, the power consumption would be:

Power (watts) = 12V x 0.5A = 6W

It’s also important to note that some LED lighting products may be rated in milliamps (mA) rather than amps (A). In that case, you’ll need to convert the current to amps before applying the formula. To convert milliamps to amps, divide the value in milliamps by 1000.

So if the device is rated at 500mA, the power consumption would be:

Power (watts) = 12V x (500mA/1000) = 6W

It’s important to be careful when measuring current and voltage, as minor measurement errors can result in large errors in the final calculation.

Calculate the power supply for LED strips

Most LED strip light suppliers from China are selling the strips by meters. As a result, the power consumption for these lights is often listed in watts per meter (W/M) on the product packaging or in the datasheet. For example, if you want to operate a 5M LED strip, you can calculate the power supply size as follows:

Power consumption (watts) = Power consumption per meter (W/M) x Length of LED strip (meters)

For example, if the LED strip has a power consumption of 8W/M and you want to use a 5M strip, the total power consumption would be:

Power consumption (watts) = 8W/M x 5M = 40W

This is just the standard calculation, but you must continue reading below to choose a suitable power supply.

Max Wattage

When selecting a LED power supply for your LED light, it’s important to consider the wattage requirements of the light. Make sure to choose a power supply that can handle a wattage higher than the wattage of your light. It’s also important to avoid pairing a LED driver with a light that exceeds the driver’s maximum wattage or uses less than half of the driver’s maximum wattage. This will ensure that the LED driver can handle the power needs of the light and will function properly.

Calculate the power reserve

Operating an LED power supply at full capacity for extended periods is not recommended. This is because the inrush current of the lamps could cause the power supply’s fuse to blow, and the power supply unit could become overheated, potentially reducing its lifespan. Additionally, a power reserve allows room for the expansion of the lighting installation.

A reserve of 20% is generally recommended. If you plan to add more LED strips, you should increase the reserve accordingly. When calculating power with a reserve, the results may be rounded up, so choosing the next larger power supply unit is advisable.

Using Unitop LED strips as an example to explain how to calculate

1. Determine which LED strip light series you will be using.

- Unitop has so many LED strip lights that you can select the most suitable strips for your projects. If you don’t know how to select, you can read this article. If you need further assistance, you can contact us directly.

- Let’s choose TB1616 Top Bend LED Neon Flex as an example)

2. Check the input voltage of the strip. It could be 12V or 24VDC.

- Most of our LED strips are 24VDC as they are becoming more common than 12VDC strips.

- Continue the above example, TB1616 Top Bend LED Neon Flex is 24VDC.

3. Find out how many watts per meter your LED strip consumes.

- Each strip has a specific power consumption per meter (measured in watts/M). This information can be found on the product page of the strip light. Knowing this will help you determine the power supply size you need. If you don’t have enough power to light your strips, the lights may appear dim, flicker, or not turn on at all.

- Continue the above example, TB1616 Top Bend LED Neon Flex is 12W/M.

4. Use this information to calculate the estimated power usage of your LED strip.

- The power requirements of an LED strip light depend on the type and length of the light strip.

- Continue the above example, if your installation requires 10M TB1616 Top Bend LED Neon Flex, it will be 12W/M*10M=120W.

5. Remember to consider the “rule of 120%”

- This rule suggests choosing a power supply with at least 120% of the LED lighting products’ total power consumption to ensure the LED strips’ proper function.

- Continue the above example. You will need 120W*120%=144W LED power supply.

6. Based on this information, determine the power supply you need for your LED strip lights.

- Our example shows that you need a 24VDC power supply with minimum 144W output.

- Sometimes, there is no same-wattage power supply, such as 144W. You must choose the nearest standard wattage LED power supply, such as 150W or 160W.

7. Finally, purchase the recommended LED power supply for your project.

After everything is decided based on the above calculation, you can go ahead to buy the LED power supply immediately.

Non-dimmable or dimmable LED power supply

LED lights and drivers can be designed to have a dimming feature, but it’s important to check the product datasheet to make sure they are labeled as dimmable. If the product specifications don’t mention dimming, likely, the product is not dimmable. This also applies to LED lights used in households with internal drivers. To use dimmable external drivers, you may need to purchase an external dimmer or other dimming control devices, as mentioned in the product datasheet.

There are two main types of dimmer control: PWM dimming and TRIAC dimming.

PWM dimming, also known as pulse-width modulation dimming, can be used on all power supplies. Even if the power supply doesn’t explicitly state that it’s dimmable, it can still be dimmed through wall-mounted or remote PWM dimmers. This is because PWM dimmers work by pulsing the lights at high frequencies, which changes the perception of light to the naked eye. The higher the frequency, the brighter the lights will appear.

TRIAC dimming allows for LEDs to be dimmed with standard dimmers. To use TRIAC dimming, you need to ensure that the power supply is compatible with alternating current (TRIAC) dimming. This can be done by checking the power supply specifications. Popular brands of TRIAC dimmers include Lutron and Leviton and they can be found in most hardware stores.

The application environment(Temperature and waterproof)

When choosing an LED power supply, it’s important to consider the application environment. Will the LED lights be used indoors or outdoors? Will they be placed in humid or wet locations? These factors will determine the type of LED power supply appropriate for your needs.

For outdoor or humid applications, choose a waterproof LED power supply with an IP rating of 65, 67, or 68. The IP rating is a two-digit code that indicates the ingress protection level of the power supply enclosure. The higher the rating, the better the protection against water and other environmental factors.

You can read our article about IP ratings for LED strips.

Temperature is another important factor to consider. LED power supplies work most efficiently within a specific range of temperatures. These devices generate heat when used, and prolonged overheating can lead to failure. To prevent this, it’s best to use LED power supplies in well-ventilated areas.

Efficiency

When it comes to powering LED lights, efficiency is vital. The efficiency of a power supply tells you how much of the power being used is going towards lighting the LED. The higher the efficiency percentage, the more energy you save. For optimal performance, choosing a power supply with an efficiency rating of 80% or higher is a good idea. Brands such as MeanWell and Phihong offer some of the most efficient power supplies on the market, with efficiency ratings reaching the 90 percentile. Choosing a power supply with a high-efficiency rating ensures that your LED lights run efficiently and cost-effectively.

Power factor

When choosing a LED power supply, it’s important to consider its power factor. The power factor measures how much of the real power load the driver places on the electrical network. The range for power factor is from -1 to 1. A power factor closer to 1 means the driver is more efficient. A standard for power factor is 0.9 or higher. If a driver’s specification does not mention a power factor, it usually means that the device has a power factor below 0.9, which is less efficient.

Small or large LED power supplies

When choosing a power supply for your LED projects, it’s important to consider where you will install it. If you plan to place it inside the product you’re creating, make sure it’s small enough to fit in the designated space. If you’re installing it outside the product, you’ll need a way to mount it nearby. Many different power supplies are available in various sizes and shapes to fit your specific needs.

Class I or class II(Class 1 or class 2) LED power supply

Regarding LED drivers/power supplies, there are two main safety classes – Class I and Class II. Class I LED drivers have basic insulation and must be connected to a protective ground to reduce the risk of electric shock. This is achieved by using basic insulation and connecting conductive parts to the earth in case the basic insulation fails, preventing the generation of dangerous voltage.

On the other hand, Class II LED drivers provide additional safety measures, such as double or reinforced insulation, in addition to basic insulation to prevent electric shock. They do not rely on protective ground or installation conditions for their safety.

UL/CE or other certificates

It’s important to choose an LED power supply that is UL/CE certified. These certifications ensure better safety compared to those that are not certified. These certifications are often required for new and remodeling projects.

Other certificate requirements from different countries for LED power supply, such as PSE, SAA, etc.

Safety protection

Safety should always be a top priority. That’s why it’s important to look for power supplies with protection features like over-current, over-temperature, short-circuit, and open-circuit protection. These features help to prevent problems by shutting down the power supply in the event of a fault. While they aren’t required by law, they are essential for safe power supply use. To ensure that you’re using your power supply safely, installing power supplies with these protection features is best.

How to guarantee the quality and dependability of LED power supply?

- When designing and producing a product, it’s important to follow a standardized process to ensure that the final product is high quality. The first step is to create an expert design and engineering prototype, followed by a small trial production.

- To ensure the product is reliable and long-lasting, it’s important to include a sensible design margin for the components used. This means selecting the highest-quality components, such as electrolytic capacitors, ICs, power semiconductors, and magnetic parts.

- To ensure that the product is of the highest quality, it’s important to have strict quality assurance and testing procedures in place. This includes tension analysis, EVT, SVT, DVT, MTBF, and other speculative verifications.

How to connect LED strips to the LED power supply?

Connecting LED strips to an LED power supply typically involves the following steps:

- Locate the positive and negative connections on the LED strip and power supply. The positive connection is usually labeled as “V+” or has a red wire, while the negative connection is marked as “V-” or has a black wire.

- Connect the LED strip’s positive connection to the power supply’s positive connection. It can be done using a connector or by soldering the wires together.

- Connect the LED strip’s negative connection to the power supply’s negative connection.

- Make sure the connections are secure and that there is no bare wire or exposed metal that could cause a short circuit.

- Plug the power supply into a power outlet and turn it on to test the LED strip.

Examples: One LED strip and LED power supply connection example as below:

Can I connect many LED strips to the same LED power supply?

Yes, you can connect multiple LED strips to the same power supply as long as the combined power consumption of all the strips does not exceed the maximum output of the power supply. It is also important to ensure that the power supply’s voltage matches the LED strips’ voltage requirements.

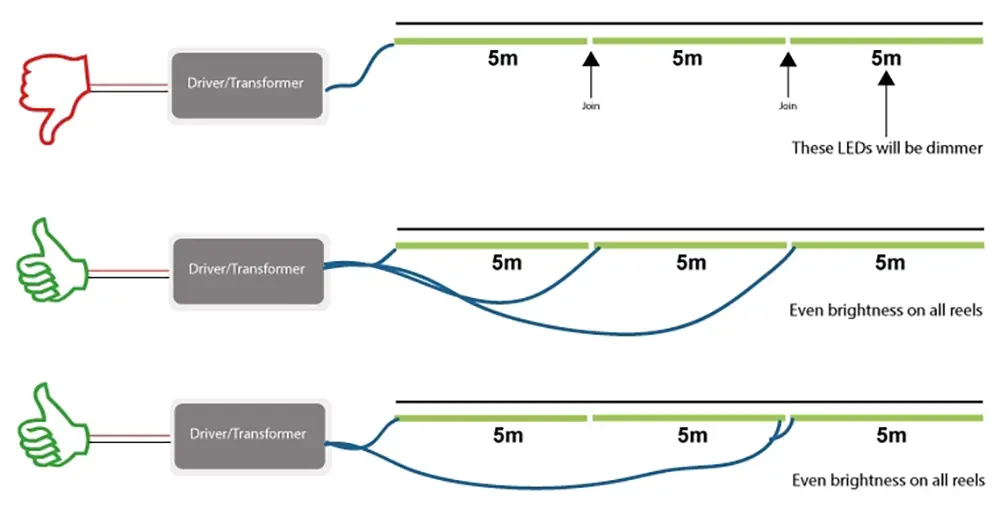

How far can I install LED strips from the LED power supply?

It is important to note that as the distance between the power supply and LED strips increases, the voltage drop across the wires will also increase. This can cause the LED strips to become dimmer or not function properly. To avoid this, you may need to use thicker gauge wires or install an additional power supply closer to the LED strips.

Some tips for installing LED power supply

- Ensure the power supply voltage matches the voltage requirements of the installed LED strips.

- Size the power supply correctly by determining the total power consumption of the LED strips you plan to connect and selecting a power supply with a matching or higher output.

- Use appropriate gauge wires for the distance between the power supply and the LED strips. The longer the distance, the thicker the gauge wire should be.

- Make sure to connect the power supply to a properly grounded outlet.

- When connecting the power supply to the LED strips, pay attention to the polarity of the connections. Incorrectly connecting the power supply can damage the LED strips or the power supply.

- Always turn off the power before installing or connecting to the power supply to avoid electric shock.

- To prevent overheating, ensuring the LED power supply is installed in a well-ventilated area is important. This allows for proper airflow and helps the power supply release heat, ensuring it operates at a suitable temperature.

- For safety and regulatory compliance, consult local codes and guidelines for installing power supplies and electrical work.

What are some common problems with LED power supplies, and how can I troubleshoot them?

Several common problems can occur with LED power supplies. Some of these include:

- Overheating: This can occur if the power supply is installed in a poorly ventilated area, causing it to release excessive heat, which can damage the unit.

- Short circuit: This can occur if the power supply is wired incorrectly or if the wiring has a problem.

- Overload: This can occur if the power supply provides more power than it is designed to handle.

- Voltage fluctuations: This can occur if the power supply is not receiving a stable voltage from the power source.

To troubleshoot these problems, you can try the following:

- Check the installation location of the power supply and ensure that it is in a well-ventilated area.

- Check the wiring of the power supply and ensure that it is wired correctly.

- Check the power supply for any signs of damage or wear and tear.

- Check the power source for any signs of voltage fluctuations.

If the issues persist after trying the above steps, it’s best to consult the manufacturer’s manual or contact the manufacturer or supplier for further assistance.

What are the top LED power supply brands?

1. Osram

OSRAM GmbH is a renowned lighting product manufacturer that caters to a wide range of industries and applications. They offer a diverse range of products, including lamps, opto-semiconductors, light-emitting diodes, electronic control gears, luminaires, and advanced light management systems. OSRAM serves customers worldwide with a global reach, providing them with high-quality and innovative lighting solutions.

2. Philips

Philips Lighting is a Dutch multinational company that specializes in the manufacture and distribution of lighting products. The company was founded in 1891 and is headquartered in Amsterdam, Netherlands. Philips Lighting offers a wide range of lighting solutions for various industries and applications, including automotive, commercial, industrial, and residential lighting. Their products include LED light bulbs, traditional incandescent and halogen lamps, as well as lighting systems and control gear. Philips Lighting is one of the leading companies in the global lighting market and has a presence in over 100 countries around the world. In 2016, Philips Lighting was spun off from Royal Philips and it became a separate publicly traded company, named Signify N.V.

3. Tridonic

Tridonic is an Austrian company specializing in developing and manufacturing electronic components for lighting systems. The company was founded in 1958 and is headquartered in Dornbirn, Austria. Tridonic is a leading supplier of lighting control gear, including LED drivers, conventional ballasts, and control systems for a wide range of lighting applications, such as commercial, industrial, and residential lighting. They provide complete lighting systems, management, and smart building solutions. Tridonic is known for its high-quality products and innovative technologies and has a presence in over 80 countries worldwide.

4. Mean Well

Mean Well is a Taiwanese company specializing in designing and manufacturing power supply units. The company was established in 1982 and is headquartered in New Taipei City, Taiwan. Mean Well offers a wide range of power supply products, including AC-DC and DC-DC converters, LED drivers, and battery chargers. Their products are used in a variety of applications, including industrial, medical, IT, communications, renewable energy, and LED lighting. Mean Well is one of the leading companies in the power supply industry, known for its high-quality, reliable, and efficient products. The company is in over 100 countries worldwide and has many certifications and approvals, such as UL, TUV, CE, CCC, and CB.

5. HEP

HEP GmbH is a German company specializing in developing and producing power supplies and battery chargers. The company was founded in 1990 and is headquartered in Wernau, Germany. HEP GmbH offers a wide range of power supply products for various industries, including industrial automation, renewable energy, medical, and lighting. Their products include AC/DC, DC/DC, and DC/AC converters, battery chargers, and customized power solutions. HEP GmbH is known for its high-quality, reliable, and efficient products and has a presence in many countries. The company has several certifications, such as CE, TUV, UL, and CUL, ensuring its products meet the highest safety standards.

6. Moso

MOSO Power Supply Technology Co., Ltd. is a well-established Chinese company founded in 2006. It specializes in designing and producing power electronics solutions and was successfully listed on the SME board of the Shenzhen Stock Exchange in 2012. The company is a recognized national high-tech company providing advanced power solutions worldwide. MOSO Power is considered a benchmark in the domestic power supply industry and is recognized as a top brand in Shenzhen, a famous trademark in Guangdong Province and throughout China.

In Conclusion

Choosing the right LED power supply for your project or application can be a complex task, but by following a few key guidelines, you can ensure that you select a product that will meet your needs and perform well. Consider the voltage and current requirements of your LEDs and the operating environment, and be sure to select a product with appropriate certifications and safety features. Additionally, it is important to select a reputable supplier who can provide technical support and answer any questions you may have. By taking the time to research and select the right power supply, you can ensure that your LED project runs smoothly and provides the desired results.

As a professional manufacturer of LED strip lights in China, we not only can produce the highest quality LED strip lighting products, but also we will be able to help you to choose suitable LED power supplies for your lighting projects. Please feel free to contact us if there is anything we can do for you.

Leave a Reply

Want to join the discussion?Feel free to contribute!

Leave a Reply

Tom is now the Sales Manager of Unitop (China) Co., Limited. He has been in the LED Lighting industry ever since 2005. He is an expert in sales & marketing, and factory management. He likes bodybuilding, and he is also a crazy Apple Fan! He is a hard-working guy and loves to learn and try new things.

Email: tom@unitopledstrip.com WhatsApp: +86-18680307140

Your valuable ideas are highly appreciated.

I am impressed with this site, really I am a big fan .

Thanks for your liking.