Can you safely mount LED strip lights on metal surfaces? The question might seem straightforward, but the answer unveils a world of nuanced considerations essential for both aesthetic allure and functional efficiency. Yes, you can, but knowing how to do it right is crucial to leveraging the benefits while mitigating any risks.

Enter Tom, a seasoned expert in the LED industry since 2005. With years of hands-on experience and a deep understanding of LED technology, Tom offers invaluable insights that bridge technical knowledge with practical application. His expertise sheds light on the intricacies of LED installations, ensuring you receive advice rooted in industry-leading practices.

This blog post will guide you through the essentials of combining LED strips with metal, from understanding heat dissipation to exploring creative and safe applications. Whether you’re a DIY enthusiast or a professional designer, you’ll discover a trove of information that can transform how you think about and use LED lighting in conjunction with metal surfaces.

So, are you ready to illuminate your knowledge and elevate your LED projects? Let’s dive right in and uncover the bright possibilities that await!

Understanding the Interaction Between LED Lights and Metal

The interplay between LED lights and metal surfaces is a nuanced one that hinges on the properties of thermal conductivity. Metals, being excellent conductors of heat, offer a unique advantage when used in conjunction with LED lights. These lights, though energy-efficient, still generate heat during operation. If this heat is not managed properly, it can adversely affect the performance and longevity of the LEDs.

When LED lights are mounted on metal surfaces, the metal can help to dissipate the generated heat away from the light source. This process can be beneficial because it potentially lowers the operating temperature of the LEDs, which is directly linked to their operational lifespan. In simpler terms, the cooler the LEDs operate, the longer they can last.

However, this benefit comes with a caveat. Not all metals dissipate heat equally, and the effectiveness of heat dissipation also depends on the surrounding environment and installation specifics. Moreover, without proper consideration of the thermal properties of both the LED and the metal, there’s a risk of overheating, which could lead to reduced efficiency or even premature failure of the LED lights.

Ensuring that the metal surface and the LED are compatible is therefore crucial. This involves understanding the specifications of the LED light, such as its heat output and operational temperature range, and matching these with a metal that has appropriate thermal conductivity properties. Moreover, the setup must be designed to allow for adequate heat dissipation, which might include considerations of the ambient temperature and airflow.

Selecting the Right Metal for Optimal Heat Dissipation

The choice of metal for mounting LED lights is not one-size-fits-all. Different metals have varying levels of thermal conductivity, which influences their ability to dissipate heat. For example, copper is known for its excellent thermal conductivity and is often used in heat dissipation applications. However, its cost and weight might not make it suitable for all situations. Aluminum, on the other hand, offers a good balance between thermal conductivity, weight, and cost, making it a popular choice for LED installations.

To select the right metal, one should consider the specific heat dissipation needs of their LED setup. This involves looking at the heat output of the LEDs and understanding the environment in which they will operate. For instance, an LED light used in an outdoor setting may have different thermal management needs compared to one used indoors. The metal choice should reflect these needs, ensuring that it can adequately dissipate heat without leading to an excessive increase in the surrounding temperature or the LED itself.

In addition to thermal conductivity, other factors like corrosion resistance, ease of installation, and overall durability should also be taken into account when selecting the metal. This holistic approach ensures that the metal not only enhances the LED’s performance through effective heat dissipation but also contributes to the overall durability and reliability of the installation.

Installation Best Practices

The proper installation of LED lights on metal is pivotal for ensuring their efficient operation and longevity. This goes beyond just attaching the lights to a metal surface; it involves considering the entire system’s thermal management, electrical safety, and mechanical stability.

Firstly, ensuring good thermal contact between the LED lights and the metal is crucial for effective heat transfer. This might involve the use of thermal interface materials (TIMs) such as thermal paste or pads, which eliminate air gaps and improve the conduction of heat from the LED to the metal.

Secondly, electrical safety is paramount. This includes making sure that all connections are secure and that there is no risk of short circuits or electrical interference. The use of non-conductive materials to isolate electrically active parts of the LED from the metal can be necessary, depending on the configuration.

Lastly, the mechanical installation should be robust to ensure that the lights remain securely in place over time, even in environments where they may be subjected to vibration or other mechanical stresses. This can involve using appropriate fasteners, brackets, or adhesives that are suitable for both the metal and the environment in which the LEDs are installed.

By adhering to these best practices, one can maximize the safety and efficiency of LED lights mounted on metal, ensuring they perform optimally over their intended lifespan.

Safety Measures for Attaching LED Lights to Metal

When it comes to integrating LED lights with metal surfaces, the focus on safety is paramount. This safety-centric approach mitigates the risks associated with overheating and potential electrical hazards. Ensuring that the LED lights are securely and safely attached to metal not only enhances their performance but also extends their operational lifespan, all while maintaining a high safety standard.

Choosing Insulating Materials

The selection of appropriate insulating materials is a critical step in the process of mounting LED lights on metal surfaces. These materials serve as a barrier that prevents direct contact between the LEDs and the metal, which is crucial for reducing the risk of heat transfer and electrical shorts.

Insulating materials come in various forms, including thermal pads, insulating tapes, and non-conductive coatings. The choice of material depends on several factors, such as the specific application, environmental conditions, and the heat dissipation requirements of the LED lights. For instance, thermal pads can be used to provide both insulation and aid in heat dissipation, offering a dual benefit.

When selecting insulating materials, it’s essential to consider their thermal resistance and electrical insulating properties. The material should effectively prevent electrical conductivity while also being able to withstand the temperatures generated by the LED lights. Additionally, the durability of the insulating material is crucial to ensure that it maintains its properties over time, especially in environments where it may be exposed to moisture, chemicals, or mechanical stress.

Ventilation and Cooling Strategies

Adequate ventilation and cooling are vital for maintaining the optimal operating temperature of LED lights mounted on metal. Without proper heat management, there is a risk of the LEDs overheating, which can lead to reduced efficiency, color shift, and even premature failure.

Ventilation strategies might include the use of spacing or standoff mounts to create air gaps between the LED lights and the metal surface, allowing for air circulation and heat dissipation. In addition, the use of fans or heat sinks can be considered in situations where passive cooling is insufficient.

For cooling, it’s essential to understand the environment in which the LED lights will operate. In enclosed spaces, active cooling methods, such as forced air cooling, might be necessary. In contrast, in open or well-ventilated areas, passive cooling might be adequate.

Implementing effective ventilation and cooling strategies not only prevents overheating but also contributes to the overall energy efficiency of the LED lighting system. By maintaining lower operating temperatures, these strategies help preserve the luminous efficacy and color stability of the LEDs over time.

Maximizing LED Lifespan with Metal Mounting

Mounting LED lights on metal surfaces offers an opportunity to leverage the thermal properties of metal to enhance the longevity and reliability of the LED lighting system. Properly executed, metal mounting can facilitate better heat dissipation, reduce thermal stress, and thereby maximize the lifespan of the LEDs.

Thermal Management Solutions

Effective thermal management is essential for maintaining the performance and extending the lifespan of LED lights. Various thermal management solutions, such as thermal pads, heat sinks, and thermal adhesive tapes, can be employed depending on the specific requirements of the installation.

Thermal pads, for example, can be used to create a thermal bridge between the LED lights and the metal surface, enhancing heat transfer while also providing electrical insulation. Heat sinks can be attached to the metal surface to increase the surface area for heat dissipation, effectively lowering the temperature of the LED lights.

When implementing thermal management solutions, it’s crucial to consider factors such as the thermal conductivity of the materials, the ambient temperature, and the heat output of the LEDs. The goal is to achieve a balance between effective heat dissipation and minimal thermal resistance, ensuring that the LEDs operate within their optimal temperature range.

Effective Mounting Techniques

The way LED lights are mounted on metal can significantly influence their thermal performance and lifespan. Effective mounting techniques ensure that the LED lights are securely attached to the metal while optimizing heat transfer and minimizing thermal stress.

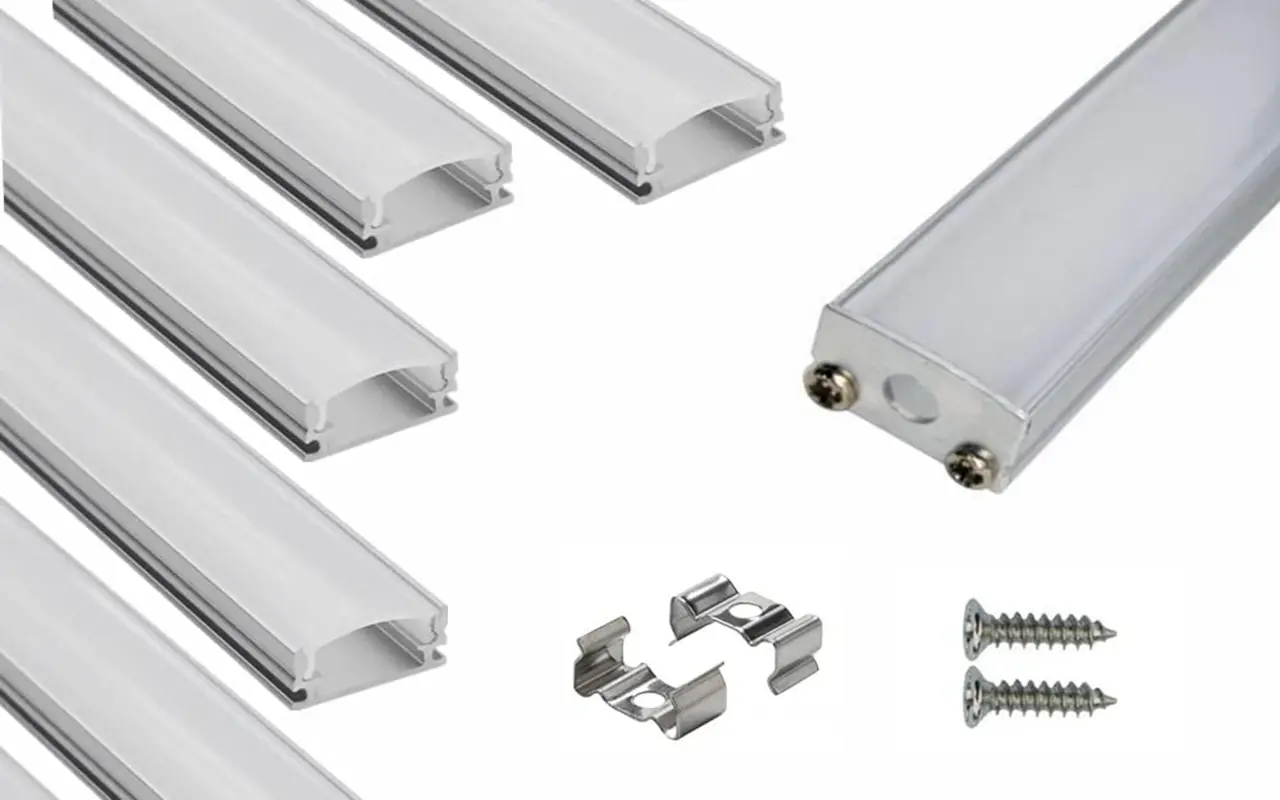

Key considerations for effective mounting include the use of appropriate hardware, such as screws or clips, that do not compromise the thermal interface between the LED lights and the metal. Additionally, the orientation and placement of the LEDs can affect their ability to dissipate heat; for example, mounting LEDs in a manner that allows for convective airflow can enhance cooling.

In situations where mechanical stress or vibration is a concern, mounting techniques that provide mechanical stability while maintaining good thermal contact are essential. This might involve the use of flexible mounts or dampening materials that absorb mechanical forces without impeding heat transfer.

By employing thoughtful and effective mounting techniques, it is possible to enhance the thermal management of LED lights, thereby maximizing their lifespan and reliability while ensuring optimal performance.

Creative and Safe Applications of LED Lights on Metal

Innovatively integrating LED lights with metal not only enhances aesthetic appeal but also serves practical purposes across various settings. Whether you’re aiming to add a touch of elegance to your living space or require durable lighting solutions for industrial environments, understanding how to safely combine these elements is crucial. Here, we delve into both decorative and functional applications, offering inspiration and practical advice to ensure safety and efficiency.

Decorative Applications

The fusion of LED lights and metal can transform ordinary spaces into enchanting environments. This synergy is not only visually appealing but also offers an array of creative possibilities:

1. Accent Lighting in Architecture: Metal fixtures with embedded LED lights can accentuate architectural features, creating dramatic effects that highlight textures and shapes. Think of a metal staircase with LED-lit balustrades or a kitchen island outlined with sleek, LED-embedded metal trim.

2. Artistic Installations: Artists and designers can harness the versatility of LED lights and metal to craft stunning installations. Whether it’s a sculptural piece where metal forms are illuminated from within or large-scale wall art that integrates LEDs for dynamic lighting, the possibilities are boundless.

3. Furniture and Fixtures: From metal tables with underlit LED edges to decorative panels that serve as both artwork and lighting sources, combining these materials in furniture and fixtures can add a modern, sophisticated touch to any interior.

To ensure safety and longevity in these decorative applications:

– Use low-voltage LED lights to reduce the risk of electrical hazards.

– Ensure that the metal used is properly treated or coated to prevent corrosion, especially in environments with high humidity.

– Consider the color temperature and intensity of the LED lights to create the desired ambiance without overpowering the space.

Functional and Industrial Uses

Beyond aesthetics, the integration of LED lights and metal is highly valued in functional and industrial contexts for its durability and efficiency:

1. Industrial Lighting: In factories and warehouses, LED lights mounted on metal structures provide bright, energy-efficient illumination. The metal enhances durability, which is essential in environments where lights may be exposed to vibrations, dust, or chemicals.

2. Outdoor Lighting: Metal poles or frames housing LED lights offer robust solutions for outdoor lighting, whether for security purposes, street lighting, or landscape enhancement. These setups are designed to withstand harsh weather conditions, ensuring reliable performance over time.

3. Signage and Wayfinding: Metal signs with integrated LED lighting not only capture attention but also remain durable and visible under various conditions. They are ideal for both indoor and outdoor navigation, offering clarity and guidance with a touch of elegance.

In functional and industrial applications, the key to safety and efficiency lies in:

– Choosing the right type of metal that can endure the specific environmental conditions without degrading.

– Ensuring that all electrical components are properly insulated and waterproofed, especially in outdoor or harsh environments.

– Regularly inspect and maintain the installations to address any wear and tear promptly, preventing potential hazards.

By carefully considering these aspects, you can leverage the durability of metal and the efficiency of LED lights to create applications that are not only functional and safe but also aesthetically pleasing. Whether in decorative or industrial contexts, the innovative use of these materials can enhance both the utility and beauty of your space.

FAQs

How does mounting LED strips on metal surfaces affect their performance?

Mounting LED strips on metal can enhance their performance by improving heat dissipation. The metal acts as a heat sink, pulling excess heat away from the LEDs, which can prolong their lifespan and improve their efficiency.

Is there a risk of overheating when installing LED strips on metal?

There is a potential risk if the metal conducts too much heat without proper ventilation. However, with adequate cooling strategies and the selection of appropriate metals, you can mitigate this risk and ensure safe operation.

What types of metal are best for mounting LED strips?

Metals with good thermal conductivity, like aluminum, are ideal as they help to efficiently dissipate heat. The choice also depends on the environment and design requirements—corrosion resistance and aesthetics may also be factors.

Can I use any type of LED strip with metal surfaces?

While many LED strips can be mounted on metal, it’s important to check the manufacturer’s recommendations and ensure that the strip’s adhesive is compatible with metal surfaces for a secure installation.

What are some creative ways to use LED strips with metal in home decor?

Consider integrating LED strips into metal furniture, under kitchen cabinets, or within metal stair railings for a modern and sophisticated look. The cool light of the LEDs combined with metal can create stunning visual effects.

Are there specific safety concerns when using LED strips with metal in outdoor settings?

Yes, outdoor installations need to consider weather resistance and proper grounding, especially when combining electricity with metal. Using weatherproof LED strips and ensuring all components are rated for outdoor use are key steps.

How can I ensure a secure attachment of LED strips to metal surfaces?

Clean the surface thoroughly before installation, use LED strips with strong adhesive backing, and consider additional mounting clips or channels for extra security, especially in high-traffic areas or where vibrations may occur.

What maintenance is required for LED strips installed on metal?

Regular inspections to check for any signs of wear, overheating, or adhesive failure will help ensure longevity. Keeping both the LEDs and the metal surface clean can also prevent overheating and maintain optimal light output.

Can the integration of LED strips and metal enhance energy efficiency?

Yes, the metal’s ability to dissipate heat can reduce the temperature of the LED strips, allowing them to operate more efficiently and use less energy over time.

What should I do if my LED strip lights installed on metal start flickering?

Check the connections and power supply first, as these are common culprits. If the issue persists, consider the possibility of thermal mismanagement or incompatibility between the strip lights and the metal surface and consult a professional if necessary.

Conlusion

In conclusion, integrating LED strip lights with metal surfaces offers a dynamic blend of aesthetics and functionality, providing ample opportunities for both decorative and practical applications. By understanding the nuances of thermal conductivity, selecting the right materials, and adhering to best installation practices, you can enhance the performance and longevity of your LED lights. Whether you’re aiming to create a captivating home ambiance or seeking efficient lighting solutions for industrial settings, the synergy between LED strips and metal can unlock innovative and energy-efficient lighting designs. Remember, the key to success lies in meticulous planning, adherence to safety guidelines, and regular maintenance, ensuring your LED installations continue to shine brightly and safely for years to come.

Delve into the world of LED innovation with Unitop, a leader in China’s LED industry, known for top-tier Fitas de LED e LED neon flex. Embrace the opportunity to collaborate with Unitop, where expertise meets quality, ensuring your lighting solutions are not just effective but also captivating. For any inquiries or specialized needs, Unitop is your go-to source. Contacte-nos now and let Unitop illuminate your space with excellence and professionalism.

Tom é agora o Gerente de Vendas de Unitop (China) Co., Limited. Ele tem estado no Iluminação LED indústria desde 2005. Ele é um especialista em vendas & marketing, e gestão de fábricas. Ele gosta de musculação, e é também um fã louco da Apple! Ele é um tipo trabalhador e adora aprender e experimentar coisas novas.

Email: tom@unitopledstrip.com WhatsApp: +86-18680307140

Deixe uma resposta

Quer juntar-se à discussão?Esteja à vontade para contribuir!